Vernier Caliper vs Micrometer

Adding this to the barrel reading of 0.275 inch gives a total measurement of 0.2947 inch. The third and fourth examples in figure 12-26 are additional readings that would require use of the vernier scale for accurate readings to ten-thousandths of an inch. Using a Micrometer. The micrometer must be handled carefully. 0 to 6' Range, 6 Rod, Satin Chrome Finish Mechanical Depth Micrometer Ratchet Stop Thimble, 2-1/2' Base Length, 0.01mm Graduation, 4mm Rod Diam MSC# 06234439 Mitutoyo (129-128).

Vernier calipers and micrometers are devices that are used in measurements. A vernier caliper is a device which consists of a ruler and a vernier scale attached to it. A micrometer, also known as a micrometer screw gauge, is a device which consists of a screw measuring system. These devices are widely used in fields such as physics, engineering, woodworking, metalworking, medicine and various other fields. In this article, we are going to discuss what are micrometer screw gauges and vernier calipers, the operating principles of micrometer screw gauge and the vernier caliper, their applications, similarities and finally the difference between micrometer screw gauge and vernier caliper.

Vernier Caliper

The vernier caliper is a device used in measurements. The vernier caliper consists of a main scale and a vernier scale which is attached to the main scale but movable throughout the length of the main scale. The vernier caliper measures the separation between the jaws of the vernier caliper.

There are inner jaws, which are used to measure internal radii or distances, and outer jaws, which are used to measure outer radii and outer distances. The main scale has separations of either 0.1 cm or 0.05 cm. A number of these separations are divided to a different number of separations inside the vernier scale. The most common of these is the 9 units of the main scale of 0.1 that are divided into 10 units inside the vernier caliper. When the jaws touch each other, the 0 of the vernier scale and the 0.0 of the main scale coincide. When the jaws are moved apart so that the 1 of the vernier scale coincides with the 0.1 of the main scale, the jaws are moved apart by a distance of 0.01 cm, which is 1/10th of the smallest reading of the main scale.

The general formula for measurements in vernier caliper is,

Smallest measurement of a vernier caliper = (Value of the smallest reading in main scale – Size of a separation in the vernier scale) * value of the smallest reading in main scale

Micrometer Screw Gauge

The micrometer screw gauge, also known as the micrometer, is a measuring instrument that is used when measuring small diameters. The basic principle of the micrometer screw gauge is that the distance a screw travels when the screw is turned by 1 complete circle is equal to the gap between two screw threads of the gauge. The screw heat attached to the screw has a scale going around the circumference of the screw head. If the circumference scale is divided into n parts and the thread gap is d mm, the smallest reading of the micrometer screw gauge is d/m mm. In a typical micrometer, the screw gap is 0.5 mm, and the scale is divided into 50 parts, which makes the smallest reading 1/100 mm. Some micrometers have vernier scales coupled to the circumference of the main body to get the smallest reading of 1 micrometer.

What is the difference between Micrometer and Vernier Caliper? • A micrometer is capable of measuring a difference as small as 0.01 mm in general cases. The vernier caliper only has the ability to measure differences as small as 0.05 in the extreme cases. • A single vernier caliper can measure inner lengths, outer lengths and depths without any change, but a micrometer can only measure one type at a time. |

Related posts:

Use of the instrument of measurement ‘micrometer’ in the metric system and centesimal resolution: reading and interpretation

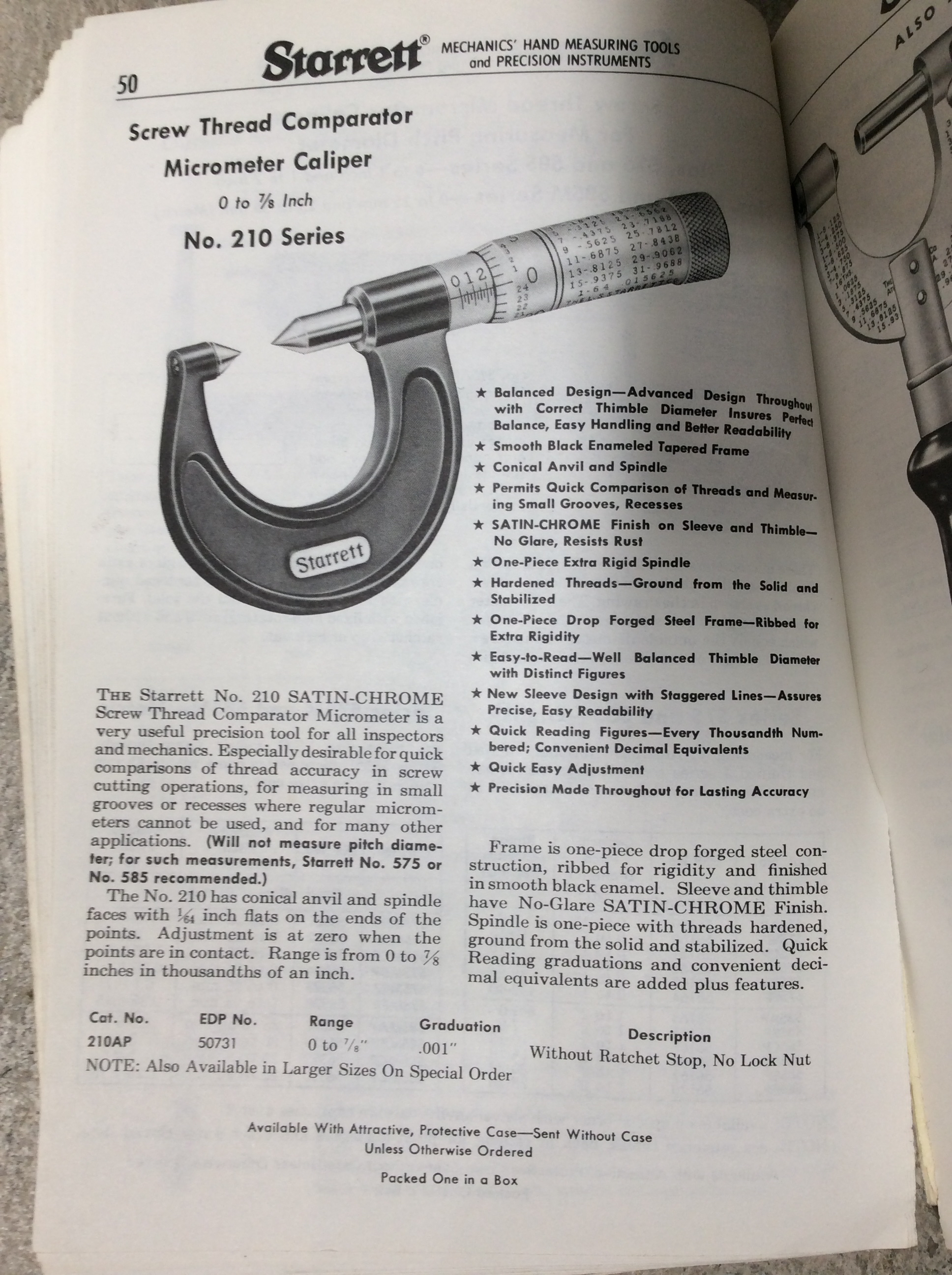

The micrometer is an instrument of portable measure, not so versatile, but with good precision when used correctly.

It is not much versatile, beyond other reasons, because its range of measurement is restricted to one inch beyond this, it has a loss of time relativily big in the tasks of adjustment of the measure to be done.

Before use: adjust the micrometer

I am using the expression ‘zero out the micrometer’ to describe the operation of adjusting the instrument which is closing it to a known extent, for example: zero or other measurement, with the aid of a standard, and aided by a suitable key, align the reference line of the sheath ‘with the zero mark (0) of the thimble. Obviously, one must use the ‘ratchet’ to close it. Incidentally, the same number of turns of the ratchet must be repeated in each measurement. See the process of taking a measurement on the page: use of the micrometer.

The micrometer operation

figure 1 – Thimble in partial view to reveal the divisions of millimeter and half millimeter in the sleeve scale

A male/ female thread pair has the pitch and calibrated settings. Solid to the spindle is the drum and its circumference is marked by equidistant lines. A complete turn of the drum (and the spindle) produces the advance equal to the pitch of the thread. This spindle, customarily, has thread of useful length a little larger than 25 millimeter.

In the sheath a graduation that controls the advancement of the drum / spindle-figure 1. Generally, these marks are 1 millimeter from the neighbors. There are also marks to control the half millimeter (0.5 mm – in this example, below the reference line), as, as we have seen, a complete revolution of the drum produced advance of 0.5 mm.

The resolution of the micrometer

By definition: ‘resolution’ is the ‘smallest difference between indications of a display device that can be significantly perceived’, it is the smallest measure that can be referenced by a measuring instrument, for example.

In the centesimal micrometer, resolution is obtained by dividing the pitch of the micrometric spindle by the number of divisions of the drum (Resolution = micrometric spindle pitch / number of drum divisions) or Resolution = 0.5 mm / 50 = 0.01 mm.

The centesimal resolution (hundredth)

figure 2 – image of graduation of the thimble scale rectified to reveal the 50 marks/divisions

Reading A Micrometer Measurement

The configuration most find in the metal mechanic offices, in Brazil, is the spindle of micrometer that has a step of 0.5mm and the thimble of 50 divisions -figure 2. This way, to turn the micrometer spindle, each mark of spindle that pass by ‘reference line’ will indicate that the mobile jamb walked away (or closer) 0.01 mm (one hundredth of a millimeter).

Reading of micrometer in centesimal millimeter

- To determine the value of teh measurement, it is necessary to sum:

- The value read in the scale graved in the sleeve, in millimeter

- Represented by (o) ‘in green color’ in the animation below

- With 0.50mm in case of the counter of half millimeter it will be exposed

- Repesented by (o) ‘in blue color’

- With the value of the spindle aligned with the ‘reference line’, in centesimal millimeter

- Repesented by (o) ‘in the orange color’

- Animation 1 – reading of the measure by the sum of the parcels

Tips

– click in the icon in the inferior corner of the animation screen 1 to change the value of the measurement

– use the icon ‘eye’ to hide the total values and partial

– with the ‘closed eye’, click in the colored circles shows the partial value related to them

Commented examples of reading and interpretation of micrometer in hundredths millimeter

Micrometer Size

Virtual micrometer in millimeter hundredths – simulator of use, reading and interpretation